ADVANTECH SOLUTIONS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ADVANTECH SOLUTIONS

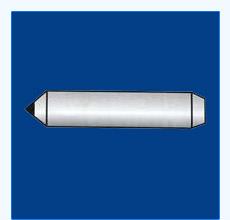

Single Point Diamond Dresser

Single point "bruted diamond" dressers are made with selected "Congo Rounds" mounted in a matrix. A Single cutting edge is presented to the grinding wheel.

Diamonds for single point dressers are selected in accordance with quality and size. The question of using a superior, average or commercial quality, depends on the grinding finish required and the machines and working parameters.

We offer three grades namely A, B & C for all the diamond size, Availability: 0.25 Ct to 5.00 Ct

Natural Point Diamonds : The Diamond points are naturally formed. (Not man made like grades A, B, & C) This is a gift of nature. Natural Point Diamond Dressers have high form retention properties. Availability: 0.10 Ct to 2.50 Ct

Guideline for Single - Point Diamond Dressers :

Considerable care should be taken in mounting the diamond dresser in position. Diamonds are sensitive to shock and impact.

The dresser must be clamped rigidly in place to avoid vibration once dressing begins.

An ample supply of coolant should be directed at the diamond point before dressing begins, as the sudden application of coolant to the diamond once it has heated up can cause it to shatter.

The diamond holder should not be set directly on the center of the grinding wheel, but at an angle of 5-15 to the direction of rotation of the wheel so that it appears to be "trailing"

At normal wheel peripheral speeds, dressing rates of approximately 20-25 m/sec can be achieved.

The maximum depth of cut achieved per dressing pass is 0.03 mm or on fine grit wheels, approximately 0.005-0.01 mm. ( Single Point Diamond Dressers )

The cross feed rate is dependent upon grit size and can have a marked influence on the quality of the finish imparted to the grinding wheel surface. The lower the feed rate, the finer the surface finish. We would recommend the following feed rates per revolution of the grinding wheel.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.